Other Equipment

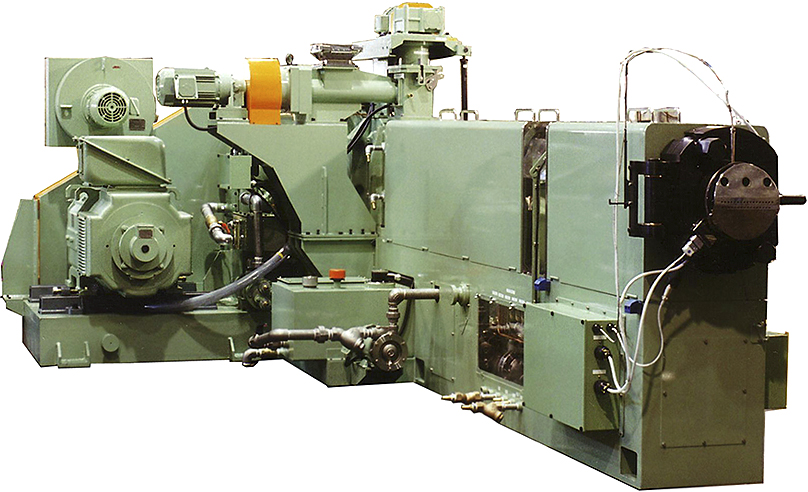

Single Screw Extruder

| Items | Features |

|---|---|

| Cylinder Material | Nitriding Steel (SACM645) Nitriding |

| Screw Material | Chromium Molybdenum Steel (SCM440) Nitriding |

| Cylinder heating/cooling | Band heater/Blower Aluminum casting heater/Water cooling |

| Cylinder Heating Control | PID Automatic Temperature Adjustment |

| Screw drive | Inverter motor |

| Opening and closing of the head and die section | Double eyebolt system, simple structure, high adhesion effect, stability, measures against resin leakage, and simplified mesh replacement |

| Head flange section | Built-in cartridge heater |

| Reduction gear | Single helical gear system for drive motor |

Basic specifications

| Items | Unit | TNEー40 | TNEー65 | TNEー90 |

|---|---|---|---|---|

| Screw diameter | mm | 40 | 65 | 90 |

| L/D | ー | 32 | 36 | 36 |

| Screw speed | rpm | ~150 | ~240 | ~240 |

| Drive system | ー | Inverter motor | ||

| Motor driving | kW | 11 | 75 | 132 |

| Power supply voltage | V | AC200 | ||

| Heating method | ー | Band heater type/Aluminum casting heater type | ||

| Discharge rate(*) | kg/h | 20~40 | 150~250 | 350~500 |

| Machine center height | mm | 1000 | ||

(*) Discharge amount is the ABS conversion value. Depends on conditions such as resin type and temperature.

Cantilever Type Pelletizer (Strand Cutter)

| Items | Features |

|---|---|

| Rotary blade holding mechanism | Cantilever type |

| Cover open/close/internal | Full open structure/Easy replacement of rotary blade and urethane roll/Reduction of color change operation time/Easy clearance adjustment of rotary blade and fixed blade |

| Material chute | Straight chute structure |

| Safety | Window-mounted Safety Cover/Cutting Section Check |

| Option | Air blower |

Basic specifications

| Items | Unit | TSCー250 | TSCー500 |

|---|---|---|---|

| Maximum capacity | kg/h | 250 | 500 |

| Maximum strand | Number | 15 | 25 |

| Peak withdrawal rate | m/min | 63 | 78 |

| Drive system | ー | Inverter motor | |

| Motor Capacity | kW | 2.2 | 5.5 |

| Power supply voltage | V | AC200 | |

| Rotating blade (base metal SUS) | ー | 12-blade cemented carbide tip | 18-blade cemented carbide tip |

| Rotary blade size | mm | φ120 × W160 | φ160 × W180 |

| Fixed blade (base metal SUS) | ー | With carbide tip | |

| Upper roll | ー | Urethane rubber-coated air cylinder pressing | |

| Bottom roll | ー | Knurling S45C HCr-plated | |

| Machine dimensions | mm | W1095 × D800 × H1620 | W1275 × D850 × H1730 |

(*)In addition to the cantilever-type pelletizer, we also produce a double-end support pelletizer.

TABATA Industrial Machinery designs and manufactures various other equipment as shown below. Please contact us for more details.

・Wire coating Equipment

・Heat shrink tube Manufacturing Equipment

・Ultra-high molecular weight polyethylene extrusion equipment (ram type)

・Extended tubing manufacturing equipment

・Etch processing system, etc.