Small Injection Molding Machine

TABATA specializes in compact and vertical injection molding machines and offer a wide range of models.

Tabletop Plunger Injection Molding Machine ※Demo units are available.

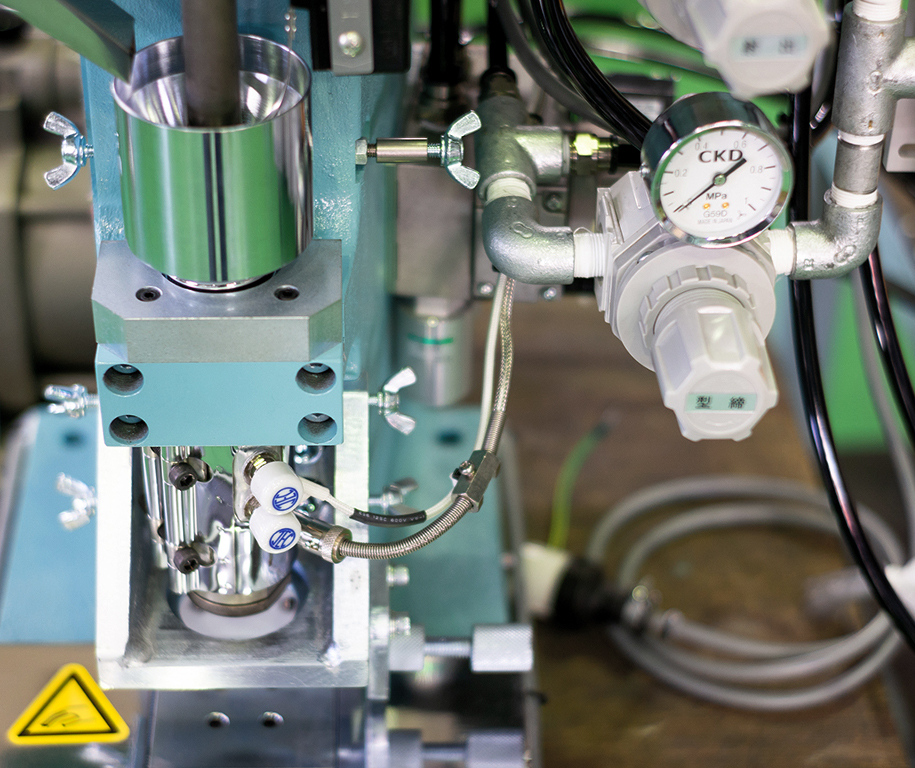

TABATA Pneumatic driven compact molding systems offer economy of size, weight, and price for small part insert molding. It utilizes factory compressed air and the power supply is 100V. The structure is tie bar less and suitable for insert molding.

It also features a tabletop compact design. It can be used in the sense of “tool”, not “machine”.

Equipment

TKPー14ー1PF / TKPー14ー1APF

Main applications

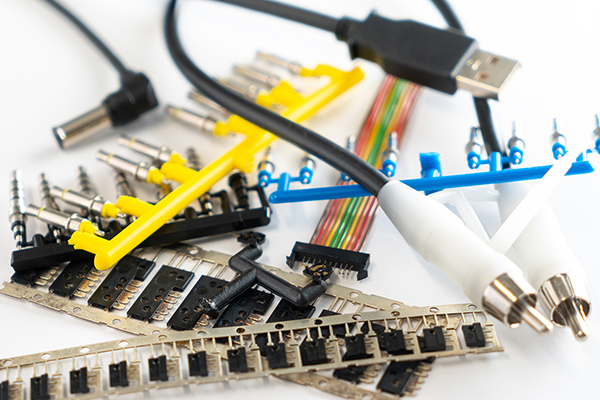

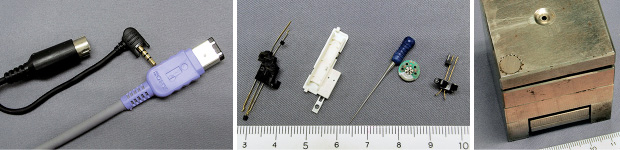

Cord terminal molding, sealing molding of semiconductor parts, parts for small insert molding, etc.

TKPー14ー1APF

TKPー14ー1PF / TKPー14ー1APF

The minimum mold dimensions can be as small as 50 × 50mm, which greatly reduces mold costs. It is compact, lightweight, and can be operated with the feeling of a “tool” rather than a “machine”, and it is easy to maintain with a simple configuration.

Basic specifications

| Items | Unit | TKP-14-1PF | TKP-14-1APF |

|---|---|---|---|

| Type | ー | Air driven plunger type | |

| Plunger diameter | mm | 10/12/16/20 | |

| Injection capacity (theoretical value) | cm³ | 3/4.5/8/13 | |

| Max. air pressure | MPa | 0.7 *0.5Mpa only when φ10 plunger is used | |

| Max. injection pressure | MPa | 111/109/61/39 | |

| Raw material hopper feed | Liter | 4 | |

| Clamping force | kN | 22 | |

| Mold clamping system | ー | Direct pressure type horizontal clamping | Direct pressure type vertical clamping |

| Frame structure | ー | C type frame | |

| Nozzle Tip Shape | ー | Flat | Sphere R10/RF |

| Nozzle pore size | mm | 2 | |

| Raw material supply method | ー | Volumetric automatic supply | |

| Temperature control | ー | 1 point | |

| Daylight | mm | 75 | 55 (50/60/65) |

| Clamping stroke | mm | 12 | |

| Basic die dimensions | mm | 80 × 80 × D50~60 | 80 × 80 × H50~65 |

| Heater capacity | kW | 0.5 | |

| Electric capacity | VA | 570 | |

| Power supply voltage | V | AC100 | |

| Machine dimensions | mm | W790 × D680 × H960 | |

| Weight of machine | kg | 150 | |

※ A dedicated table with casters is available as an option.

●There is demonstration machine "TKP-14-1PF".

Screw Injection Molding Machine ※Demo units are available.

With remaining of good features of tabletop plunger type injection molding machine, hydraulically driven unit for screw injection is used in order to process wide range of materials with high precision. For higher production volumes we offer automated units with slide tables and turntables.

Equipment

TSー5ーDV8

TSー5ーAV8ーSE

TSー5ーAV8ーTE

Main applications

Compact component engineering plastic molding, connector terminal molding,

Lead frame molding, etc.

TS-5-DV8 (tie bar less tabletop)

The smallest vertical screw type tabletop injection molding machine. It is a machine with excellent cost performance due to space saving, molding stability and high operability. It is optimal for precision molding of small parts.

TSー5ーDV8

Basic specifications

| Items | Unit | TSー5ーDV8 |

|---|---|---|

| Type | ー | Hydraulically driven screw type |

| Screw diameter | mm | 16/18 |

| Injection capacity (theoretical value) | cm³ | 9.0/11.4 |

| Max. injection pressure | MPa | 122/96 |

| Injection rate | cm³/sec | 19.4 / 24.6 |

| Clamping force | kN | 43.6 |

| Mold clamping method | ー | Direct pressure type, lower mold rising type |

| Frame structure | ー | C type frame |

| Nozzle touch inrush amount | mm | 3 from platen surface |

| Daylight | mm | 80 |

| Clamping stroke | mm | 15 |

| Max. mold size | mm | W100 × D100 × H70 |

| Temperature adjustment | ー | 3 points (2 cylinders, 1 nozzle) |

| Hydraulic Pump Motor Capacity | kW | 2.2 |

| Electric capacity | kVA | 5.2 |

| Power supply voltage | V | AC200 |

| Machine dimensions | mm | W650 × D630 × H981 |

| Weight of machine | kg | 200 |

●There is demonstration machine "TS-5-DV8".

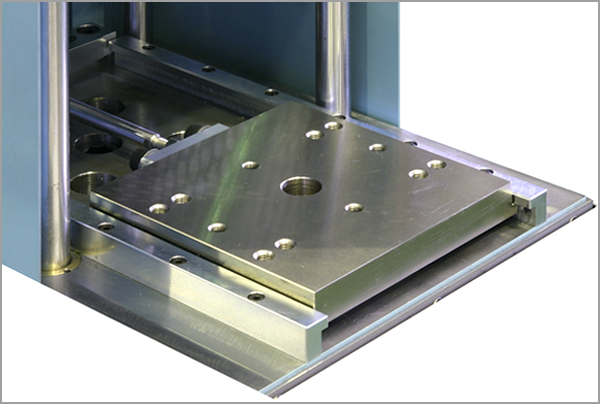

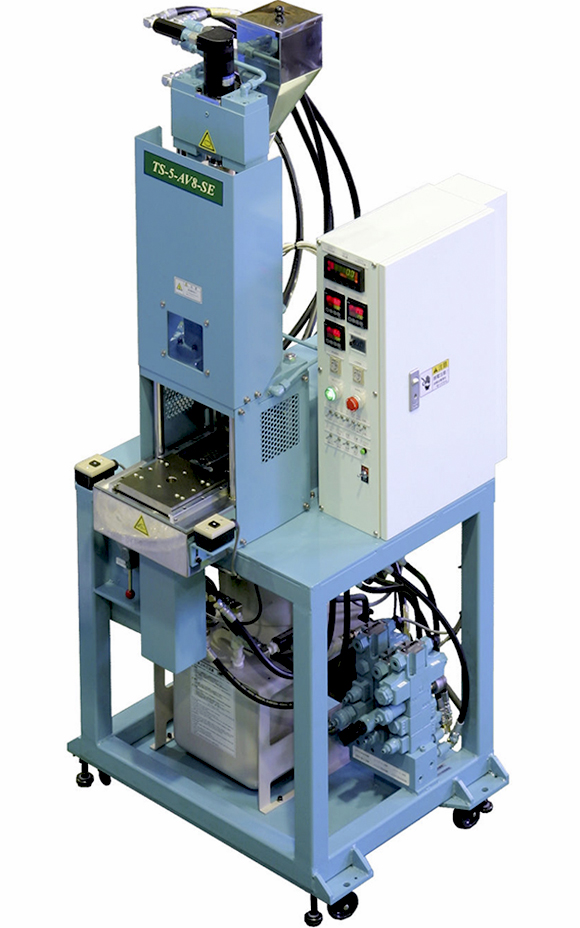

TSー5ーAV8ーSE

(tie bar type slide table mechanism)

Although it has the same function as the TS-5-DV8, it is equipped with a back-and-forth slide mechanism for the mold mounting part with an improvement on efficiency and safety. It is the most suitable molding machine for in-line molding.

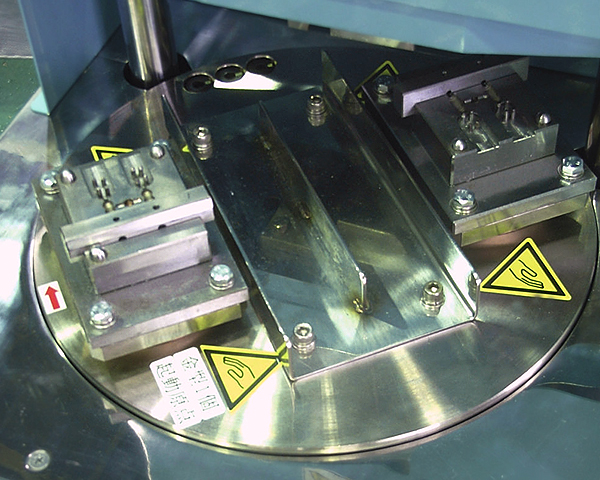

TSー5ーAV8ーSE slide section

TSー5ーAV8ーSE

Basic specifications

| Items | Unit | TSー5ーAV8ーSE |

|---|---|---|

| Type | ー | Hydraulically driven screw type |

| Screw diameter | mm | 16/18 |

| Injection capacity (theoretical value) | cm³ | 9.0/11.4 |

| Max. injection pressure | MPa | 122/96 |

| Injection rate | cm³/sec | 19.4/24.6 |

| Clamping force | kN | 43.6 |

| Mold clamping method | ー | Direct pressure type, lower mold rising type |

| Frame structure | ー | 4 tie-bar type |

| Nozzle touch inrush amount | mm | 6 from platen surface |

| Daylight | mm | 160 |

| Clamping stroke | mm | 45 |

| Tie-bar inside dimensions | mm | W190 × D140 |

| Lower mold mounting plate dimensions | mm | W150 × D150 |

| Slide stroke | mm | 150 |

| Eject stroke | mm | 25 |

| Temperature adjustment | ー | 3 points (2 cylinders, 1 nozzle) |

| Hydraulic Pump Motor Capacity | kW | 2.2 |

| Electric capacity | kVA | 5.2 |

| Power supply voltage | V | AC200 |

| Machine dimensions | mm | W785 × D763 × H1797 |

| Weight of machine | kg | 385 |

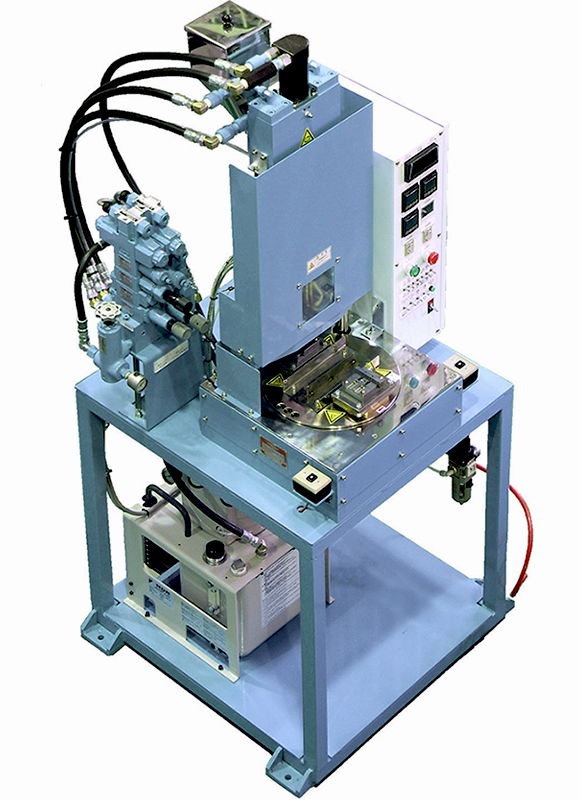

TSー5ーAV8ーTE

(tie bar turntable mechanism)

It has the same function as the TS-5-DV8, but forming cycle is improved.

TSー5ーAV8ーTE turntable section

TSー5ーAV8ーTE

Basic specifications

| Items | Unit | TSー5ーAV8ーTE |

|---|---|---|

| Type | ー | Hydraulically driven screw type |

| Screw diameter | mm | 16/18 |

| Injection capacity (theoretical value) | cm³ | 9.0/11.4 |

| Max. injection pressure | MPa | 122/96 |

| Injection rate | cm³/sec | 19.4/24.6 |

| Clamping force | kN | 43.6 |

| Mold clamping method | ー | Direct pressure type, lower mold rising type |

| Frame structure | ー | 2 tie-bars |

| Nozzle touch inrush amount | mm | 6 from platen surface |

| Daylight | mm | 120 |

| Clamping stroke | mm | 45 |

| Tie-bar inside dimensions | mm | 250 |

| Dimensions of lower die mount plate | mm | W120 × D80 |

| Eject stroke | mm | 25 |

| Temperature adjustment | ー | 3 points (2 cylinders, 1 nozzle) |

| Hydraulic Pump Motor Capacity | kW | 2.2 |

| Electric capacity | kVA | 5.2 |

| Power supply voltage | V | AC200 |

| Machine dimensions | mm | W795 × D720 × H1736 |

| Weight of machine | kg | 450 |